automatische Kaltziehmaschine für Messingdrahtkabel zum Binden von Drähten

Marke: youmale

Herkunftsland: China

Technische Unterstützung: Lange Lebensdauer

Trockendrahtziehmaschine mit hoch- und niedrigkohlenstoffhaltigem Draht,

Edelstahldraht und Legierungsdraht mit Sensorarm und Tanzarm

Einlassdraht: 2,0 - 18mm

Trommelgröße: 200 - 1200mm

continuous straight copper wire drawing machine

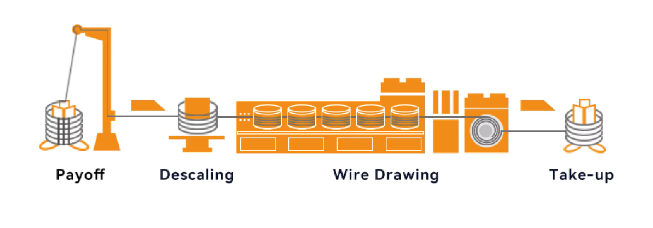

In the wire drawing machine production process, greenland youmale technology has moved away from the traditional approach of using a single model to draw wires of various materials.

Instead, wires of different materials are now drawn using specific models tailored to each material.

Additionally, depending on the wire rod's specifications, various models from the same series are dedicated to specialized machines.

The drawing process wire drawing machine is also adjusted based on the material of the wire rod.

This system is designed to work with various types of steel wire, including high, medium, and low carbon wires, as well as specialized wires like stainless, prestressed, bead, hose, spring, and cord steel. It employs a slit water cooling system for the reel and direct water cooling for the wire drawing die, ensuring optimal cooling performance. Air tension is used for tuning, providing stability during the drawing process.

The machine is user-friendly, with easy threading and operation, and ensures that the steel wire remains untwisted, resulting in high-quality final products. Its process flexibility allows for adjustable jump modes, accommodating various production needs. Additionally, the system offers remote diagnosis capabilities via Ethernet.

For safety, it features a fully enclosed protection system with multiple safety functions. It utilizes advanced AC frequency conversion control, PLC programming, and a screen display, offering a high level of automation. The electric control system is built on field bus technology and is fully digital, ensuring reliable and stable operation.

The system is compatible with a variety of pay-off and take-up machines, including I-wheel, duckbill, cantilever, and hydraulic up-draw pay-off machines, as well as I-wheel, trunk, inverted, and loose frame take-up machines.

wire drawing machine specification

| Straight drawing machine main technical data | ||||||

| Drum diameter (mm) | ф400 | ф600 | ф750 | ф850 | ф900 | ф1000 |

| Inlet wire range (mm) | 1.8-2.5 | 3-7 | 6.5-9 | 8-12 | 10-16 | 12-18 |

| Drawing speed (m/min) | 30-60 | 60-120 | 60-120 | 40-90 | 40-90 | 40-60 |

| power(kw) | 11-15 | 37-55 | 45-75 | 55-90 | 75-130 | 75-130 |

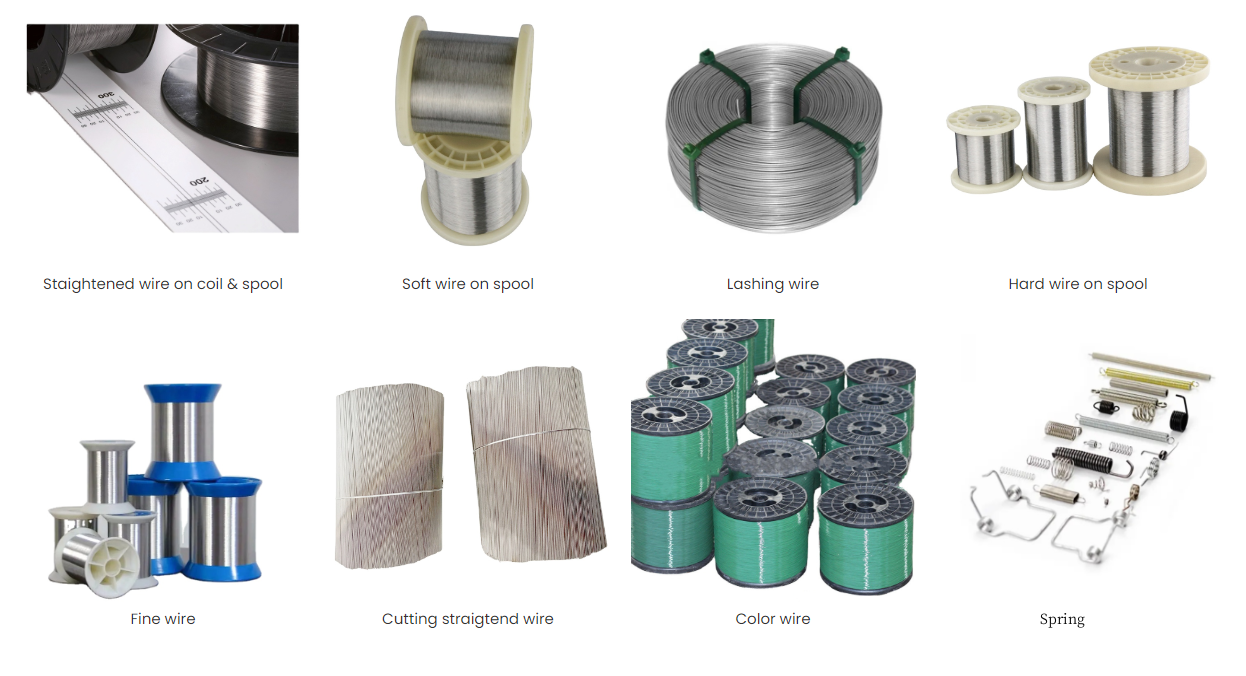

Application